Xiamen ZoneWu LoRaWAN water quality pH monitoring sensor is a wireless IoT device that can collect and monitor water quality data and transmit the data. It follows the standard LoRaWAN protocol and can communicate easily even at long distances. The sensor comes with automatic temperature compensation and is very convenient to use. The scheme of electric power supply is also flexible. It can be connected to external DC power supply or use battery. It can work normally under various conditions.

Product Model :

LW102-pHPower Supply Mode :

Battery or External DCFrequency :

CN470/IN865/EU868/RU864/US915/AU915/ KR920/AS923-1&2&3&4MAC Version :

LoRaWAN 1.0.3Mode :

OTAA Class A/CWeight :

150gIndustrial-Grade LoRaWAN Water Quality pH Monitoring Sensor

xiamen ZoneWu LoRaWAN water quality pH monitoring sensor is used to measure the pH of a solution. It can automatically adjust the result of a measurement according to the temperature, and can switch between automatic and manual temperature compensations.

xiamen ZoneWu LoRaWAN water Quality PH Monitoring Sensor Features:

This PH sensor is an integrated design, no cumbersome parts, the overall structure is simple and lightweight.

Because of its simple structure, it is very convenient to use, and the operation is not complicated.

It can be connected to an aviation connector and a LoRaWAN collector, and then the measured data can be wirelessly transmitted to a very long distance.

Rely on internal components to accurately detect the pH value of the solution and quickly determine the pH value.

There is an automatic temperature compensation function, the measured data is accurate, and the temperature compensation mode can be switched automatically and manually.

It is suitable for use in weak acid and weak alkali environments without strong corrosion, such as industrial wastewater and domestic sewage monitoring, and can also be used in agriculture, aquaculture and other industries.

Technical Parameters

|

Power Supply |

DC12/24V |

|

Weight |

150g |

|

Operating Emperature |

0~40℃ |

|

Measuring Range |

0~14.00PH |

|

Measurement Error |

±0.15PH |

|

Resolution Ratio |

0.01PH |

|

Temperature measurement range |

0~60℃,Resolution Ratio:0.1℃ (When manually compensating for temperature, it is set to 25 ℃ by default.) |

|

Electrode usage cycle |

6-12 months |

|

Pressurization |

0.6Mpa |

|

DO Transmitter Line length |

Default 5m (other lengths can be customized) |

|

Frequency |

CN470/IN865/EU868/RU864/US915/AU915/ KR920/AS923-1&2&3&4 |

|

Mode |

OTAA Class A/C |

|

Reporting cycle |

External power supply:10min(Default reporting cycle) |

|

Communication Protocol |

LoRaWAN,LoRa TDMA Networking |

|

Equipment information (Reference) |

AppEUI:0000000000000001 DevEUI:aaaa202404150001 AppKey:00001111222233334444555566667777 MAC Version:LoRaWAN 1.0.3 |

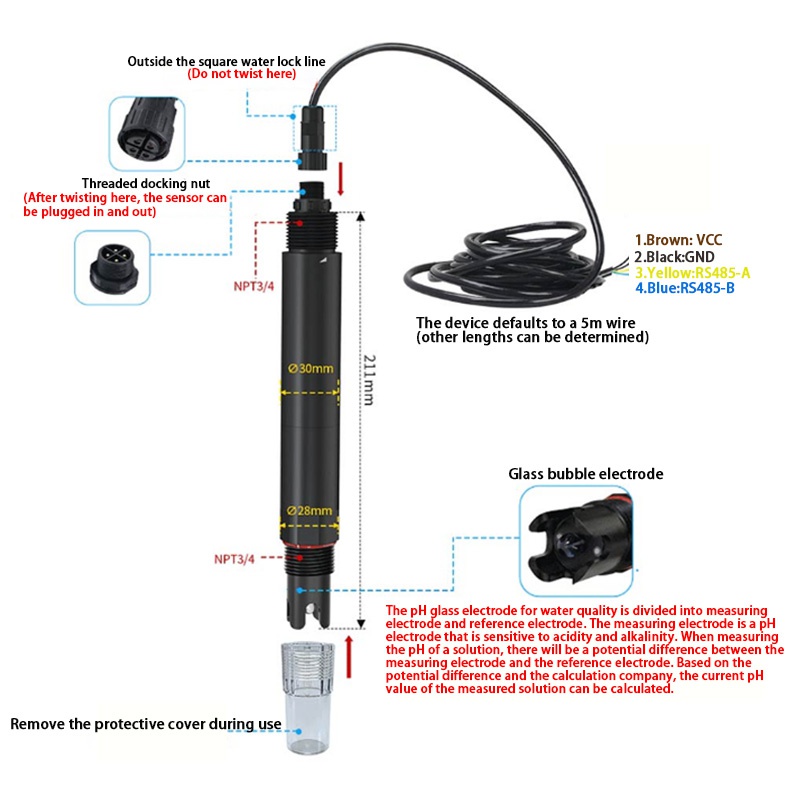

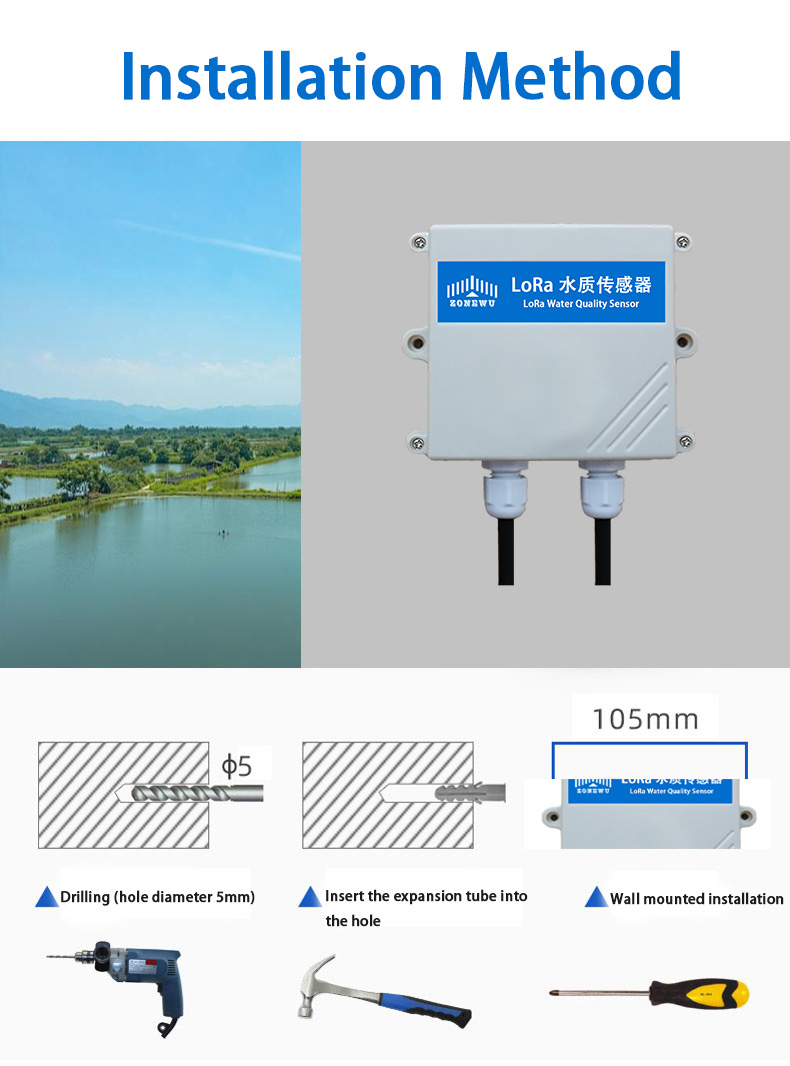

pH Transmitter Size and Installation

1. Submerged installation: The lead wire of the equipment is passed through the waterproof pipe, and the 3/4 thread on the top of the equipment is connected with the 3/4 thread of the waterproof pipe with raw material tape. Make sure that the top of the equipment and the equipment lines are free of water.

2. Pipe Installation: Connect to the pipe through the 3/4 thread of the device.

Common knowledge of pH Monitoring

Why must the liquid PH be measured using an electrode sensor with automatic temperature compensation

The pH of a solution changes in real-time with the temperature of the solution being measured, but the vast majority of the measured solution temperature changes with meteorological conditions. Therefore, it is necessary to use an electrode sensor with automatic temperature compensation to measure the pH of a liquid.

The pH value in aquaculture is in the dangerous range, why is the probability of fish death a large span

In the aquaculture industry, if the pH value is below 4.4, the mortality rate of fish can reach 7% to 20%. If the pH value is below 4, all fish will die; The mortality rate can reach 20%~89% when the pH value is above 10.4, and it can cause complete death when the pH value is above 10.6.

The water quality standard only stipulates the range of PH, how can the testing method ensure that the water quality is qualified

The latest water quality standards for domestic drinking water (2006) and natural mineral water (2008) issued by China have a pH range of 6.5-8.5, without specific explanation, only specifying the testing methods. Therefore, the normal pH of weakly alkaline natural drinking water should be greater than 7 and less than 8.5.

Application Scenarios

Aquaculture

Monitor the calcium ion concentration of aquaculture bodies to ensure the health of aquaculture organisms and the stability of water quality.

Seawater Monitoring

Monitoring the concentration of calcium ions in seawater is conducive to marine ecological research and the regulation of seawater aquaculture.

Industrial Wastewater

Monitoring the concentration of calcium ions in industrial wastewater helps with wastewater treatment and achieving compliance with discharge standards.

A:Yes,we can provide you with OEM services and design housings and logos.

3.DO you offer free samples?

A:Sorry,we don't offer free samples.After ordering in bulk,we will deduct the sample fee from the second order.

Why Choose ZONEWU